Continental are a unique brand in cycling. The proudly German company has its roots deep in the highest echelons of German manufacturing for over 150 years. The brand’s technology and development centre in Korbach is the home to the latest advancements which have improved the quality of cycling tyre performance through the constant developments to both materials and processes of manufacture. Being a large global player in the tyre market for all vehicles, Continental have production facilities around the world, however these all adhere to strict quality guidelines from the Korbach plant.

Continental is a big company. You may think you know how big they are. But they’re bigger than that. They employ nearly 250,000 people globally. Okay, so the tyre division of Continental isn’t all of that. The tyre division only(!) has around 50,000 employees and has sales well into billions of euros – So, Still, pretty big.

Continental don’t just make tyres. They have divisions working in diverse areas across the automotive industry from infotainment and connectivity to electrical energy storage systems in the latest Electric Vehicles.

Continental Timeline

1871 – Continental founded in Hanover, Germany. Amongst various soft rubber goods and rubberised fabrics, Continental manufacture solid tyres for bicycles.

1882 – The rampant horse motif is first used as Continental’s logo.

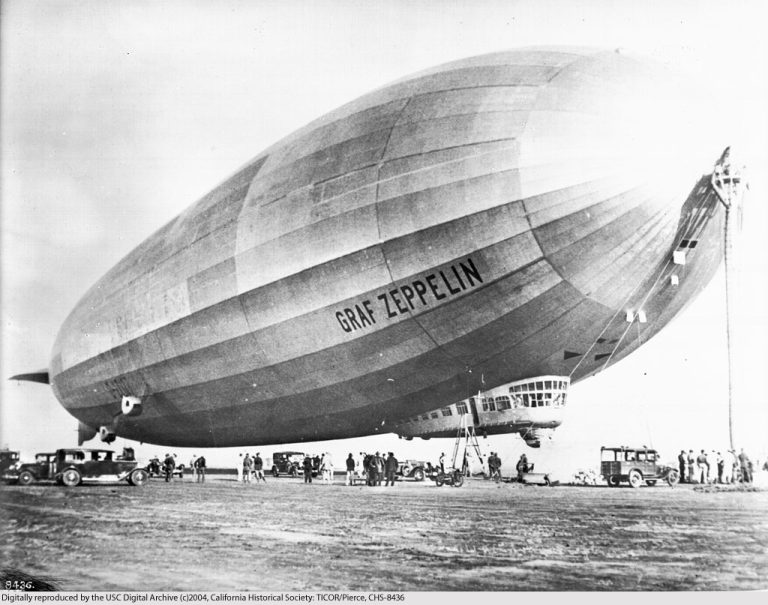

1900 – The first German airship – the LZ 1 – uses Continental rubber balloon material for containing the gas.

1904 – Continental produce the world’s first automotive tyre that has a patterned tread on it.

1909 – Continental begin their relationship with the world of synthetic rubber. Using synthetic rubber created by Bayer laboratories, Continental successfully vulcanise it and make some early prototype tyres.

1921 – Continental pioneer the use of cord fibre carcass which results in a much less stiff tyre carcass compared to existing linen carcass designs.

1926 – A substance called ‘carbon black’ is added to Continental’s tyres which results in better durability and ageing. It also makes them look REALLY black which the general public seem to like.

1936 – Synthetic rubber is finally introduced properly into Continental’s manufacturing process.

1943 – Continental file a patent for tubeless car tyres.

1955 – Continental begin manufacture of tubeless car tyres.

The modern era

In more recent years Continental has seen competition success across all areas of bike riding, there are literally too many successes to list, however here are some milestones from a UK perspective.

1980’s – Saw the first edition Continental Grand Prix clincher which offered tubular-like performance for road riders.

1992 – Olympic high performance 110g track tyres on the famous Lotus bike of Chris Boardman – Gold Olympic 4000m Pursuit.

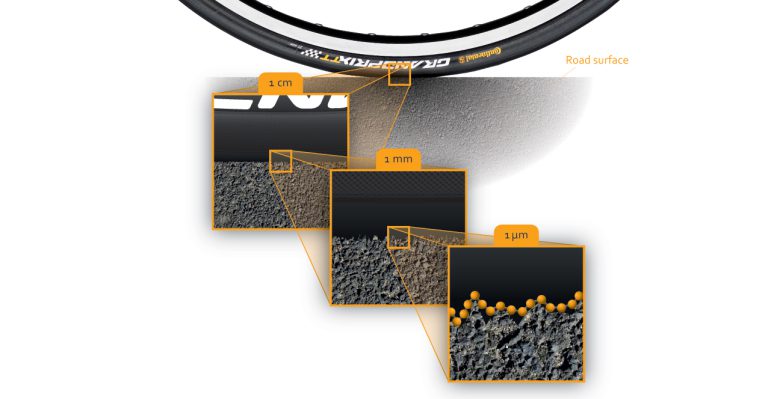

2005 – Continental made their next big leap with synthetic rubber technology. The name for the whole project was ‘Black Chili’. Essentially Black Chili is a rubber compound made from a proprietary mix of natural rubber and synthetic rubber with a magic ingredient of carbon soot particles.

2015 – Continental Competition Tubular tyres TDF winner Chris Frrome Team Sky

2016 – Continental Competition Tubular tyres TDF winner Chris Froome Team Sky

2017 – Continental Competition Tubular tyres TDF winner Chris Froome Team Sky

2018 – Continental Competition Tubular tyres TDF winner Geraint Thomas Team Sky

2019 – Continental Competition Tubular tyres TDF winner Egan Bernal Team Ineos

2021 & 2022 – World Tour Team Tyre supply; Team Ineos, Groupama FDJ, Arkea Samsic, Bahrain Victorious, Movistar, Wanty

2022 Continental Highlights

GP5000 S TR

The race results for the GP5000 S TR tyre speak volumes for its performance at the highest level. Both the Paris Roubaix and the World Time Trial Championships were won on the GP5000 S TR. Continental managed to make this tyre 50 grams lighter, more grippy and more puncture proof than the previous edition. Continental achieved this wizardry through a comprehensive re-design of the tyre, moving from three layers to two and removing the inner layer of rubber which allowed the previous GP5000 TL version work without sealant. So like other tubeless tyres the GP5000 S TR needs sealant. The tyre features Black Chilli tread rubber and the Vectran puncture resistant strip.

GP5000 Clincher

The GP4000S II was a very good tyre, much loved by road riders all over the world. So, when Continental launched the GP5000 clincher in 2018 and announced; 12% better rolling resistance, 20% increased puncture protection together with improved grip and comfort, oh and it’s lighter too, it is fair to say eyebrows were raised. However, nearly four years after the GP5000 tyre launched, these claims were very well-founded. The GP5000 clincher is a brilliant road tyre, especially when matched with a lightweight inner tube, such as the Continental Supersonic.

Gatorskin Clincher

Puncture protection is a vital ingredient for tyres, particularly in winter when roads are in worse condition and cold fingers make punctures more difficult to swap inner tubes. Continental Gatorskins have developed an unrivalled reputation for resisting punctures. The cut resistant Duraskin layer protects the whole tyre, while the puncture proof Poly X Breaker (a densely woven, highly resistant, polyester fibre) resists penetration through the tread, preventing punctures. With a weight of 250 grams for the 25mm folding gatorskin, they have proven to be very popular amongst UK road riders.

Terra Gravel

Continental’s gravel bike tyre range is available in 27.5″ and 700c, it is also split into two types of tyre; The Terra Trail TR has smaller centre knobs and chunkier side shoulder knobs for grip in a variety of conditions and surfaces including muddy trails. The lighter treaded Terra Speed TR features smaller, more spaced knobs, lower rolling resistance and is more suited to dry, dusty and loose gravel tracks and trails.

‘Beefed-up’ MTB Range

2022 has seen a sharper focus on MTB tyres, largely thanks to collaboration and feedback from professional athletes such as the Athertons. The latest range is designed TR (Tubeless Ready) around 27.5 & 29er wheels with widths of 2.4 and 2.6. The model name on the sidewall is joined by 3 symbols which identify the type of tyre. The tyres are available in DH, Enduro and Trail casings and different rubber compounds.

The Xynotal is ideal for hard, rocky terrain with large knobs to provide a grippy contact patch on hard surfaces. The Kryptotal are all-rounder tyres, the only ones to be front and rear specific. The front tyre offering stability and control. The rear has different sized knobs and negative spaces to offer grip over varied terrain for enhanced braking power, grip and stability. Argotal is designed for loose surfaces including dusty conditions – the wide, open tread pattern allows for self cleaning, reinforced shoulder knobs allow extra cornering grip and stability. The Hydrotal is focused more on wet and muddy terrain. The open tread allows for self cleaning and reinforced shoulder knobs add stability. The Hydrotal is designed as a Downhill racing tyre and has a DH specific casing and soft rubber compound.