Handlebars Guide

Regardless of what type of handlebars you use, they all offer a level of comfort and control for your ride. The seemingly subtle differences of shape, width and angle can hugely effect rider comfort, control and weight distribution.

.jpg)

How Do They Work?

Handlebars connect to the fork steerer tube using a handlebar stem. Handlbars are used to mount brake / gear lever controls as well as accessories such as bells and bike computers.

What Types of Handlebars are there?

There are two main types of handlebars, flat and drop handlebars.

Flat handlebars are used on mountain bikes, hybrids and flat bar road bikes. Flat handlebars are not really flat, they have some sweep or rise to help comfort.

Drop handlebars are found on road bikes of all types, except time trial / tri bikes, which use a base bar with clip on tri bars. In general, flat bars tend to be wider at the grips and offer more control. Drop bars tend to be narrower and allow for multiple hand positions.

A recent variation on the drop handlebar is the Gravel bar which flares out wider in the drops of the bar, to aid control. Aero drop bars with a flattened section on the tops are also popular, many riders also find these bars provide a more comfortable hand position as well as aero gains from providing less surface aero at the front of the bike.

Sizing & Fit

Handlebar diameter changed around 20 years ago when ‘oversize’ 31.8mm replaced the old 25.4 size for road bikes and 26mm for MTB. This bigger diameter enabled stiffer bars and stems and also made things easier for manufacturers who made both road and MTB components. The 31.8mm diameter is measured at the wider section in the center of the handlebars. Now 31.8mm handlebars are the ‘norm’ for drop and flat handlebars. Some manufacturers have gone bigger with a 35mm bar / stem interface, particularly in mountain biking, where wider handlebars benefit from a more substantial junction between bar and stem.

The width of flat bars is relatively straight forward, the end to end length is the measurement. In recently MTB bars have been getting wider as many riders prefer the added control, the downside, however, is more width to squeeze the through gaps between trees and other obstacles. With drop handlebars, different manufacturers measure their bars differently. Deda for example measure centre to centre, where Cinelli measure outside to outside.

Drop Handlebar Sizing

Width of drop handlebars has always been a source of debate. Back in the old days, bars used to be the width of riders shoulders, more recently as aerodynamics have become more mainstream, narrower bars have got more popular amongst riders looking at taking advantage of aerodynamics.

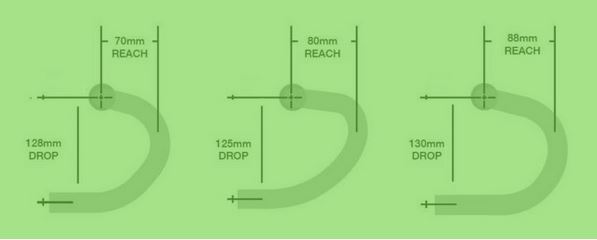

Reach of drop handlebars is the distance between the flat top of the bars at the stem and the furthest part forward, where the levers attach. A longer reach will stretch riders out more, a shorter reach bar will bring the bars nearer and make the rider sit more upright.

The drop of bar is also another variable. Shallow drop bars keep the more upright when riding on the drops. Deep drop bars keep a rider lower at the front when riding on the drops.

Flat Handlebar Sizing

Riser bars are lower at the centre and higher at the grips, they give a higher riding position compared to a flat bar. A bar with a 40mm rise will feel taller than a flat bar. The sweep / back sweep of the bar is the amount that the bars curve towards the rider, the degrees of sweep is a personal choice, the sweep gives a more natural had position on the grips. A bar with 5 degrees of sweep is often a good choice for cross country riders. Up sweep is equivalent to rise and is popular on Enduro / All Mountain bikes.

Materials

Handlebars were traditionally made from steel, until the early 1960’s when Cinelli developed the first aluminium handlebars. Aluminium bars then gradually became common place on most bikes above entry level. Today most bars are aluminium, some are still steel (mainly at entry level) and some are carbon fibre. The benefits of carbon in handlebars is that they can absorb some road / rough surface / trail vibration, they also tend to be lighter in weight than aluminium alternatives. The downside to carbon bars is that they can more fragile and develop fractures from crashes and knocks, carbon bars also tend to be more expensive. Aluminium bars are generally robust and last a long time, they can withstand knocks and crashes, aluminium bars tend to be less expensive than carbon fibre.